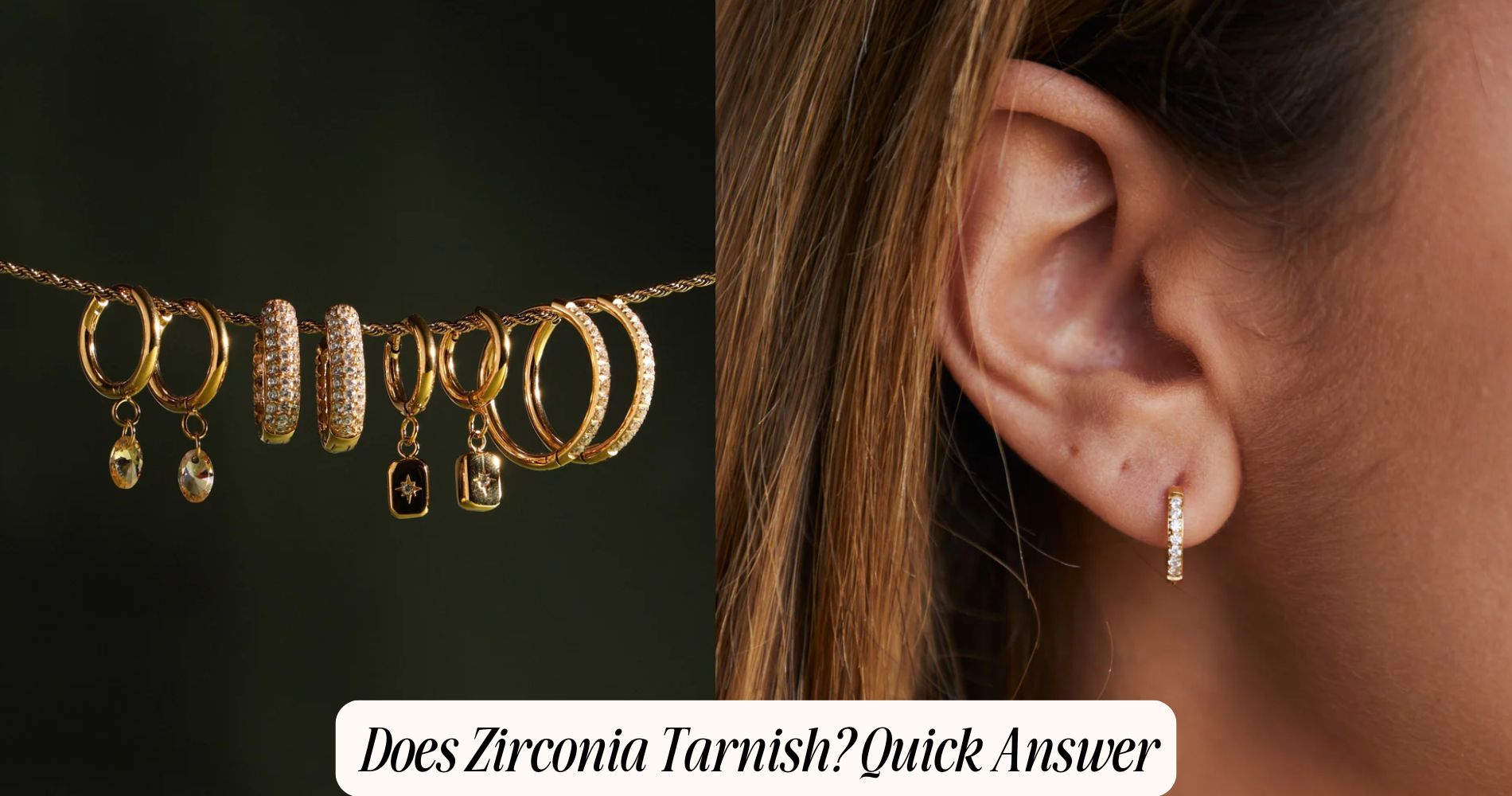

Does Zirconia Tarnish? Quick Answer

Does zirconia tarnish? Zirconia itself doesn’t undergo traditional tarnishing because it’s a chemically inert ceramic with a dense zirconium–oxygen lattice that resists oxidation and surface reactions. Any dullness or discoloration you notice usually comes from metal settings, surface coatings, residue buildup, or microscopic contaminants—not from the zirconia stone itself. These effects are typically reversible with gentle, non-abrasive cleaning or professional polishing. For high-clarity designs that showcase zirconia’s lasting brilliance, explore pieces from our Stone Collection—then continue for exact causes, safe cleaners, and long-term care tips.

Quick Answer: Does Zirconia Tarnish?

Wondering if zirconia tarnishes? You won’t see conventional tarnish on zirconia because its ceramic lattice lacks metallic free electrons and reactive surface oxides that drive sulfide or oxide films.

Based on zirconia properties, chemical inertness and a stable Zr–O bond network minimize surface reactions with atmospheric sulfur or oxygen species.

In practice, microcontaminants or deposited metals can discolor a zirconia surface, but the substrate itself remains chemically resistant.

For tarnish prevention, you’ll focus on contamination control: avoid contact with metal particulates, store items in clean, low-humidity environments, and clean with non‑abrasive, pH‑neutral solutions.

Routine inspection and gentle maintenance will preserve appearance; aggressive cleaners or abrasives can introduce defects that mimic tarnish.

Why Zirconia Resists Tarnish

Because zirconia is a covalently dominated ceramic with a dense, oxygen‑terminated surface network, it lacks the free metallic electrons and reactive surface oxides that drive classical tarnish reactions; the Zr–O bonds form a stable, low‑mobility lattice that resists sulfur or oxygen adsorption and subsequent sulfide/oxide film growth.

You’ll find that low electronic conductivity and high surface energy reduce chemisorption kinetics, so contaminant species have limited adherence and diffusion.

Crystal phase stability (tetragonal/cubic retention) and minimal grain‑boundary activity further limit reactive sites. Those durability factors predict long-term inertness under normal environmental exposures.

If you apply controlled surface treatments, like polishing or low‑temperature vitrification, you can reduce defect density and maintain that inert surface, reinforcing the material’s resistance to conventional tarnish pathways.

When Zirconia Can Look Tarnished (Coatings, Settings, Buildup)

One common scenario where zirconia can appear tarnished is when surface coatings, metal settings, or accumulated deposits alter its optical or surface properties rather than the ceramic itself corroding.

You’ll see dulled luster when plating or thin-film coating types (PVD, sputtered oxides) degrade, delaminate, or change refractive index; the substrate remains chemically stable but light scattering increases.

Metal settings can shadow edges or introduce galvanic discoloration at interfaces, producing a perceived tarnish line.

Organic and inorganic buildup causes — skin oils, sulfide particulates, polishing residues, or lime scale — create diffuse films that reduce specular reflection.

You should inspect coating condition, junctions with metal components, and quantify deposit composition; cleaning or re-coating restores original optical performance in most cases.

Spot Real Damage Vs. Surface Dulling

How can you tell whether a localized defect on zirconia is true material damage or merely surface dulling? You inspect the site under magnification, lighting, and tactile test.

Spot damage penetrates the glaze or bulk: you’ll see fractures, chipping, or exposed grain structure with sharp edges and subsurface cracks on microscopic exam.

Surface dulling shows uniform loss of specular reflectance, micro-scratch networks, or thin contamination layers that polish out without loss of geometry.

Use low-power microscopy (10–40×) and cross-polarized light to reveal depth and crack propagation; measure roughness (Ra) to quantify surface mattification.

Probe gently with a stylus to check for material removal. If structure and dimensions remain intact, it’s surface dulling; if microfractures or material absence occur, classify it as spot damage.

Zirconia Cleaning: Home and Pro Methods

After you’ve distinguished true material damage from surface dulling, decide whether the affected zirconia needs cleaning or repair; many apparent defects respond to proper cleaning and polishing rather than replacement.

For routine zirconia maintenance, you’ll use nonabrasive methods: warm water, neutral pH detergent, and a soft brush remove debris without altering surface microstructure.

For stubborn residues, clinical studies support ultrasonic baths with approved cleaning solutions at controlled temperatures and exposure times; follow manufacturer concentration and rinse thoroughly.

For lab or dental prostheses, consider professional repolishing with fine diamond pastes and controlled-speed polishers to restore gloss without inducing phase transformation.

Document pre- and post-cleaning surface roughness (Ra) and color metrics to confirm restoration and maintain service records for longevity.

What to Avoid: Cleaners and Harmful Practices

Because zirconia's surface chemistry and phase stability are sensitive to pH, temperature, and mechanical abrasion, you should avoid alkaline or strongly acidic cleaners, high‑concentration peroxide solutions, and any abrasive scrubs that increase surface roughness (Ra) or introduce microcracks.

Don’t use household bleach, concentrated ammonia, caustic cleaners, or undiluted hydrogen peroxide; these cleaning agents can destabilize the tetragonal phase, promote low‑temperature degradation, or etch grain boundaries.

Avoid ultrasonic baths at elevated temperatures with aggressive detergents and prolonged exposure to steam or autoclave cycles that may induce phase transformation.

Refrain from mechanical polishing with coarse abrasives or wire brushes that generate subsurface damage.

These harmful practices accelerate roughening, reduce flexural strength, and compromise long‑term structural integrity.

Caring for Zirconia Jewelry, Crowns, and Tools

The precautions above inform practical care routines for zirconia items—jewelry, dental crowns, and cutting or measuring tools all share vulnerabilities to chemical attack, thermal exposure, and mechanical abrasion, so your maintenance should minimize those risks while preserving surface integrity and fit.

You’ll rinse regularly with neutral pH detergent and deionized water to remove contaminants; avoid ultrasonic cleaners above manufacturer-recommended power and duration to prevent phase transformation.

For crowns, follow your prosthodontist’s polishing schedule to maintain marginal fit and reduce plaque retention.

For tools, inspect edges and calibration frequently; abrasive regrinding must use compatible abrasives and controlled cooling to preserve tetragonal phase stability.

For jewelry maintenance, store pieces separately, limit chlorine and acid exposure, and document any surface changes for prompt professional review to extend zirconia durability.

Buying Tips: Choose Zirconia That Stays Looking New

When you’re shopping for zirconia pieces that keep their appearance, prioritize material specification and manufacturing history: choose fully sintered, yttria‑stabilized tetragonal zirconia (3Y‑TZP or higher yttria content for translucency) with documented sintering temperature and grain size control, low porosity, and a proven surface finish protocol (mechanical polishing or low‑temperature glazing) to minimize monoclinic transformation and surface roughening over time.

Inspect supplier data: ask for XRD reports, grain-size distribution, and porosity measurements; these durability factors predict phase stability and wear resistance. Favor pieces with certified surface treatments and certified gentle colorants rather than surface coatings prone to abrasion.

Balance aesthetic choices—translucency, color matching, and finish—against technical specs. Choose vendors with traceable process control and clear warranty terms tied to measured material properties.

Fast Care Checklist: Keep Zirconia Shiny

If you want zirconia pieces to retain their polished luster, follow a short, evidence‑based care checklist that minimizes surface abrasion, chemical attack, and phase transformation.

Handle items with clean, dry hands and store them separately in soft, nonabrasive pouches to prevent micro‑scratch propagation.

Clean routinely with a soft microfiber cloth and mild, pH‑neutral detergent; rinse with deionized or distilled water and dry immediately to avoid mineral deposits.

Avoid ultrasonic cleaners, strong acids, bases, and bleach, which can induce surface degradation or tetragonal-to-monoclinic transformation in zirconia ceramics.

When polishing is needed, use only manufacturer‑recommended diamond paste at low pressure to preserve the glazed surface.

These care techniques and maintenance tips will maximize optical performance and structural longevity.

Frequently Asked Questions

Can Zirconia Cause Allergic Skin Reactions?

Yes — you can experience zirconia allergies causing skin irritation, but it's rare; pure zirconia is biocompatible, yet impurities, surface treatments, or metal substructures can provoke contact dermatitis in sensitized individuals, per clinical reports.

Is Zirconia Dishwasher-Safe for Tools and Parts?

Yes — you can usually run zirconia tools and parts in a dishwasher; zirconia durability resists corrosion and thermal stress, but validate for specific zirconia grades and fixtures per manufacturer guidelines, as zirconia applications vary by composition.

How Long Do Zirconia Coatings Last on Instruments?

You’ll see zirconia coatings last from several months to over a decade depending on application, wear, and environment; zirconia durability is high with proper zirconia maintenance, routine inspections, and controlled abrasion, contamination, and chemical exposure.

Can Zirconia Be Resized or Repaired Like Metal?

You generally can’t resize zirconia like metals; its ceramic structure limits plastic deformation. For repairs you’ll use adhesive bonding or laser-assisted glazing. Consider zirconia durability and zirconia applications when choosing restoration versus replacement.

Does Heat or UV Light Damage Zirconia Over Time?

No — heat and UV rarely damage zirconia over time; you’re safe because zirconia durability stems from its stable ceramic crystal structure. However, extreme temperatures or prolonged zirconia exposure to harsh UV combined with coatings can cause surface changes.

Conclusion

Zirconia itself doesn’t tarnish because it’s a stable ceramic oxide; you won’t get the oxidation or sulfide films that darken metals. You can, however, see surface film, coated-layer wear, or residue from settings and skin oils that make it look dull. Clean gently with mild soap, ultrasonic or steam when appropriate, and avoid abrasives or harsh acids. Inspect for real damage (chips, fractures) versus removable buildup, and store pieces to minimize surface contamination.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.